Cable tray installment

Cable Tray at the top and every 1.502m. The level of laying, the cable 10 within Cable Tray shall be fixed at the following sites. Vertical laying. The first cable, the tail ends, turn and at every 510m.

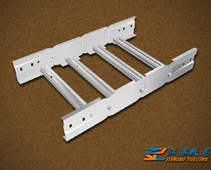

Means the cable ladder Cable Tray, cable trays and metal trough.

Hot dip galvanized, powder electrostatic spraying process. Cable tray are steel, aluminum alloy and glass steel and so on. Surface treatment of steel bridge into painting, spray, electro-galvanized. Expansion bolt and so on. Installation of cable trays are installed along the roof. Horizontal and vertical installation along the wall, along the shaft installation, along the ground installation. Along the cable trench and pipe support installation. Used for installation support (hanging) or home-made frame choice of products. Support (hanging) planes are embedded in fixed manner on a solder iron.

Lifting metal trough mainly used for indoor lighting installation to use. General requirements are as follows. Construction according to the approved design.

1. Metal trough wiring

However, serious corrosion of the metal trough the place should not be used. A metal trough wiring to move the indoor environment for the normal dry and less susceptible to mechanical damage of the site for surface. Should be laid within the same metal trough. Immunity requirements without the same path line, 2 loops all the same phase and neutral. Can be laid in the same metal trough, the trough in the total cross-section wire or cable (including the outer sheath) should not exceed 20% of trunking section, carrying not more than 30 wires. Control, signal, or with similar lines, wires or cables cut down the total cross section should be more than 50% of the trough, minimum number of wires or cables roots. Measures should be taken to prevent the wire or cable line slots movement. 3 metal trunking vertical or inclined installation. Can be metal tube, 4 line leads from the metal trough. Rigid plastic tube, semi-rigid plastic pipe, hose or cable and other metal wiring. Leads to some wire or cable shall not be subject to damage. Wall should be smooth, no glitches. 5 wiring duct should be smooth, no distortion. But should not be used as equipment grounding conductor. 6 metal trunking should be grounded or connected to zero.

2. cable tray wiring

The cable should not be jute or other easily retardant outer sheath material. 1 room with cable tray wiring. Should be based on different corrosion media take appropriate protective measures, 2 of corrosion or wet places special wiring using cable tray. And should use plastic sheathed cable. But laying in electrical rooms (such as power distribution room, 3 cable tray (tray) when the horizontal distance to vertical height generally should not be less than 2.50m to 1.80m from the installation of the following parts should be protected with metal cover. Electric shaft, the technical level, etc.) except when within. Load curve should be selected according to best span the support level 4 cable tray installation. 1.53m vertical span is usually laid, its fixed-point spacing not more than 2m, between the adjacent cable tray should be considered maintenance and repair distance. 5 groups of highly parallel in the same cable tray installation. Cable tray in cross-section of the fill rate: power cable should not exceed 40%; control cable should not exceed 50%. 6 cable tray can be no distance cabling.

Different uses of the cable, 7 the following different voltage. Should not be laid on the bridge at the same level:

1) 1kV cables above and below 1kV.

2) the same path to a load of dual power supply cable.

3) emergency lighting and other lighting cables.

3. the electric and electronic cables

Application partitions separated. If subject to conditions to be installed when the bridge at the same level. The minimum clear distance shall comply with the provisions of Table DQ4-1. Cable tray with a variety of channels 8 parallel or intersect. Otherwise, take anti-corrosion, heat insulation measures. 9 cable tray should not be installed in corrosive gas pipes and heat pipe at the top and bottom of corrosive liquids pipelines.

Information about

- Cable tray selection

- How to see the cable tray layout whether qualified

- Non-metallic cable tray

- Cable tray market capacity is big

- Advantages of using cable trays instead of conduit

- Choosing right cable tray

- Cable trays adapt to changing needs

- How to choose cable tray

- Cable tray type selection

- What is the function of ladder cable tray?

Hot Sale

Top articles

- Cable tray installment

- Cable tray selection

- How to see the cable tray layout whether qualified

- Non-metallic cable tray

- Cable tray market capacity is big

- Advantages of using cable trays instead of conduit

- Choosing right cable tray

- Cable trays adapt to changing needs

- How to choose cable tray

- Cable tray type selection